Our diaphragm vacuum pump, like circulating water vacuum pump and rotary vane vacuum pump, is a machine that provides a vacuum environment for the equipment. The equipment supporting the diaphragm vacuum pump includes: rotary evaporator, short path distillation, vacuum drying oven, vacuum suction filter, etc.

What is a diaphragm vacuum pump?

Diaphragm pump, also known as control pump, is the main type of actuator, which receives the control signal output by the modulation unit. Diaphragm pumps are powered by power to change the flow of fluid. There are four materials for diaphragm pumps: plastic, aluminum alloy, cast iron, and stainless steel. Diaphragm pumps use nitrile rubber, neoprene rubber, fluorine rubber, polyvinylidene fluoride and polytetrahexaethylene respectively according to different liquid media. to meet the needs. It is placed in various special occasions to pump various media that cannot be pumped by conventional pumps. It is especially suitable for rotary evaporators and basically meets the requirements of conventional solvents.

The working principle of laboratory diaphragm vacuum pump

Laboratory Diaphragm vacuum pumps are commonly used equipment in laboratories and are often used in conjunction with rotary evaporators. The simple working principle of the diaphragm vacuum pump is: the circular motion of the motor makes the diaphragm inside the pump reciprocate through the mechanical device, thereby compressing and stretching the air in the pump cavity to form a vacuum, and generating a pressure difference between the suction port and the external atmospheric pressure. , Under the action of the pressure difference, the gas is sucked into the pump cavity, and then discharged from the exhaust port.

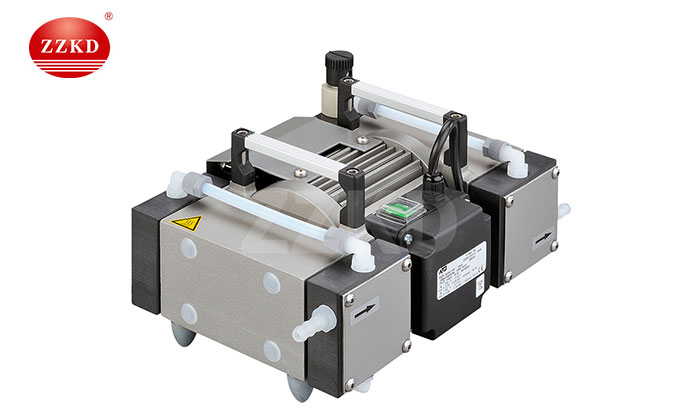

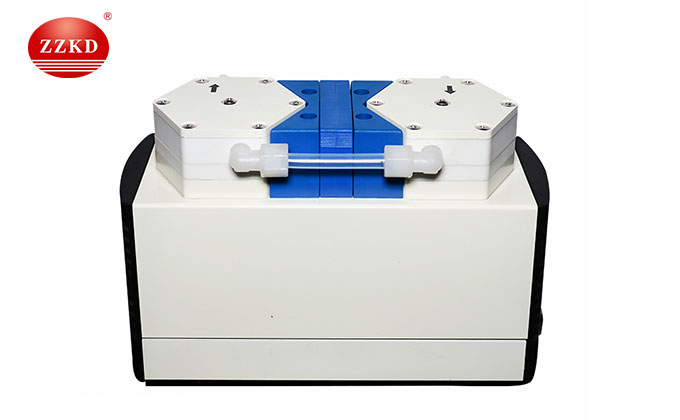

Laboratory diaphragm vacuum pump models and components

Laboratory diaphragm vacuum pumps are divided into two series: DP series and MPC series, DP series has only one model: DP-01-20, MPC series has four models; MPC201 T, MPC301 Z, MPC601 T, MPC1201 T.

The laboratory diaphragm vacuum pump is mainly composed of the transmission part and the diaphragm cylinder head. The transmission part is a driving mechanism that drives the diaphragm to agitate back and forth. Its transmission forms include mechanical transmission, hydraulic transmission and pneumatic transmission, among which hydraulic transmission is widely used. The working part of the laboratory diaphragm vacuum pump is mainly composed of crank connecting rod mechanism, plunger, liquid cylinder, diaphragm, pump body, suction valve and discharge valve, etc. Among them, the driving mechanism composed of crankshaft connecting rod, plunger and liquid cylinder and the reciprocating column Plug pumps are very similar.

When the diaphragm pump is working, the crank connecting rod mechanism drives the plunger to reciprocate under the drive of the motor, and the movement of the plunger is transmitted to the diaphragm through the working liquid in the liquid cylinder, so that the diaphragm is agitated back and forth. The diaphragm should have good flexibility and good corrosion resistance, and it is usually made of PTFE, rubber and other materials. The pot-bottom-shaped parts with mesh holes on both sides of the diaphragm are provided to prevent excessive deformation of the diaphragm, and are generally called diaphragm limiters. The air-operated diaphragm pump has good sealing performance and can easily achieve leak-free operation. It can be used to transport corrosive liquids such as acid, alkali, salt, and high-viscosity liquids.

The steps of using the mini diaphragm vacuum pump

Take the application of mini diaphragm vacuum pump in rotary evaporator as an example:

1. Put the mini diaphragm vacuum pump on the operating table smoothly, and connect the rotary evaporator with the vacuum pump tightly to ensure that the system has good air tightness.

2. Turn on the power switch. When the vacuum pump is connected to an external load, the pointer of the vacuum gauge turns counterclockwise. When the vacuum pump reaches the maximum working pressure, turn the adjusting knob clockwise to turn on the power. When the pump is working normally, the required working pressure can be obtained by adjusting the knob.

3. Inflation operation: Before the diaphragm vacuum pump operates, inflate the air chamber first, and its air pressure is greater than the working pressure of the pump to drive the diaphragm vacuum.

Adjust the pump to the working pressure. At this time, it can be seen that the water outlet hose of the pump vibrates violently; take a needle and press it against the air nozzle to deflate. As the deflation proceeds, the shaking phenomenon of the water outlet hose will gradually disappear. After it stabilizes, stop deflating.

4. The rotary evaporator adjusts the height and rotation speed of the distillation flask, and sets the appropriate water bath temperature. After steaming, stop the rotation first, then ventilate the atmosphere, then stop the water pump, and finally remove the distillation flask

5. Pressure system operation: The instrument air and lubricating oil pressure of the diaphragm vacuum pump are interlocked with the main motor. The oil injection and oil discharge valves of the propellant are air-closed valves, and a certain air pressure must always be maintained, even after the pump is stopped. Keep the instrument air in order to avoid insufficient or excessive liquid in the propellant chamber. The air supplied to the valve is filtered and oil-atomized.

6. After filtering, turn off the power.

The advantages of mini diaphragm vacuum pump

1. No need for any working medium (no oil), no pollution, at the same time, the gas exchange chamber of the machine is built with filter material, thus ensuring the purity of the air.

2. New technology and new materials are used in production. It is easy to move and work smoothly, thus ensuring ideal vacuum and high air flow rate.

3. Use friction film motion that does not generate heat and has no friction loss. The diaphragm is made of imported rubber, which is corrosion resistant and has a long life.

4. The body is designed with a self-cooling and exhaust system, which can ensure 24-hour continuous operation

5. The pressure-adjustable design can meet the vacuum degree and gas flow rate within a certain range.

6. The bearing adopts imported classic bearings, with stable operation, low noise and high work efficiency.

Mini diaphragm vacuum pump features

1. Save the space of the laboratory, and carry a built-in wrench.

2. It is convenient to be matched with the rotary evaporator, and the whole system is designed for the same brand of equipment.

3. The operation is simple and convenient, without the trouble of changing the oil in the oil pump and changing the water in the water pump.

4. The diaphragm vacuum pump can be equipped with a solvent recovery device, and the solvent can be recovered twice during the exhaust process.

5. The exhaust speed selector switch design is set according to different uses, which can be used for high-speed exhaust or for silent decompression.

6. Diaphragm vacuum pump, with lower noise, can be directly connected to the vacuum controller, and can reach the vacuum degree faster than the ordinary type.

7. Standard equipped with a gas vibration valve, when the gas vibration valve is opened, the organic solvent pumped into the diaphragm pump can be discharged through the gas vibration valve;

It can effectively protect the diaphragm pump and reduce the loss of the diaphragm, but the opening of the gas vibration valve will affect the vacuum degree.

Application of mini diaphragm vacuum pump

Mini diaphragm vacuum pumps are widely used in scientific research, medical treatment, instrumentation, chemical analysis, biological engineering, automatic control, environmental protection, water treatment and many other fields. Especially the laboratory diaphragm vacuum pump, most laboratory equipment will be equipped with a vacuum pump, because the vacuum pump is not a single device, it can be used with other instruments. Such as vacuum filtration, microbial detection, waste liquid extraction, rotary evaporator, vacuum drying oven, freeze dryer and other equipment. A vacuum pump is an auxiliary device in every laboratory.

Parameter

Model | Voltage (V) | Ultimate vacuum (mbar) | Flow rate (m3/h) | Flow rate (L/min) |

MPC301Z | 220 | <8 | 2.3 | 38.3 |

MPC302Z | 220 | <5 | 2.6 | 43 |

MPC201T | 220 | <2 | 2.0 | 33.3 |

MPC601T | 220 | <2 | 3.9 | 65 |

MPC602T | 220 | <2 | 3.9 | 65 |

MPC1201T | 220 | <2 | 8.3 | 138 |

Model | Voltage (V) | Ultimate vacuum (mbar) |

MPC301Z | 220 | <8 |

MPC302Z | 220 | <5 |

MPC201T | 220 | <2 |

MPC601T | 220 | <2 |

MPC602T | 220 | <2 |

MPC1201T | 220 | <2 |