The freeze dryer we produce and supply is a small food freeze dryer, ideal for home use to preserve fruits, vegetables, meat, and other foods. It uses vacuum freeze-drying technology to remove moisture through sublimation, while retaining nutrition, flavor, and freshness. This process creates delicious food that can be stored long-term.

Features:

⦁ High refrigeration efficiency.

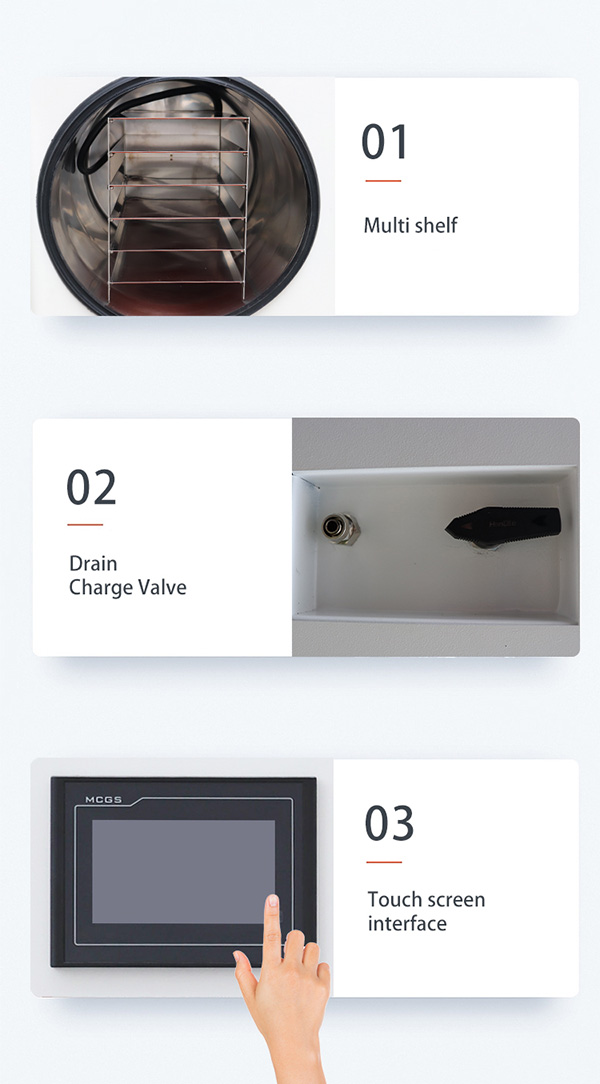

⦁ Touchscreen with intuitive display.

⦁ Food-grade stainless steel construction—hygienic and durable.

⦁ Utilizes advanced international technology, retaining 97% of nutrients.

⦁ Easy to operate and maintain.

Benefits of Freeze-Dried Food

⦁ Nutrient Retention: Freeze-drying preserves up to 97% of the food's original vitamins, minerals, and flavor.

⦁ Long Shelf Life: Freeze-dried foods can last for years without refrigeration, making them perfect for long-term storage.

⦁ Preserves Texture & Flavor: Unlike traditional drying methods, freeze-drying maintains the food’s original texture, taste, and appearance.

⦁ No Preservatives Needed: Foods are naturally preserved without the use of additives or chemicals, offering healthier and cleaner eating options.

⦁ Reduces Food Waste: Freeze-drying extends the life of perishable foods, helping to minimize waste.

Applications of the Small Food Freeze Dryer

Fruits

Example:strawberries, apples, bananas.

Vegetables

Example:peas, carrots, spinach.

Meats

Example:chicken, beef, fish.

Dairy Products

Example:yogurt cubes, cheese.

Meals

Example:soups, stews, pasta.

Pet Treats

Example:freeze-dried raw dog or cat food.

Coffee

Example:instant freeze-dried coffee.

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

Parameter

Model | FD-04H | FD-06H |

Freeze-drying area | 0.4 square meters | 0.56 square meters |

Layer spacing | 32 (mm) | 54 (mm) |

Tray size | 205*385*15 (mm) 5 pieces | 220*510*15 (mm) 5 pcs |

Freeze-dried material | 3~5 KG | 5~7 KG |

Cold trap limit temperature | -60 degrees | -60 degrees |

Power | 1300w | 2300W |

Vacuum degree | ||

Voltage | 220V 50HZ | 220V 50HZ |

Product size | 450*610*760 (mm) | 620*694*1098 (mm) |

Product weight | 130 KG | 190 KG |

Model | FD-04H | FD-06H |

Freeze-drying area | 0.4 square meters | 0.56 square meters |

Layer spacing | 32 (mm) | 54 (mm) |

Tray size | 205*385*15 (mm) 5 pieces | 220*510*15 (mm) 5 pcs |

Freeze-dried material | 3~5 KG | 5~7 KG |

Cold trap limit temperature | -60 degrees | -60 degrees |

Power | 1300w | 2300W |

Vacuum degree | ||

Voltage | 220V 50HZ | 220V 50HZ |

Product size | 450*610*760 (mm) | 620*694*1098 (mm) |

Product weight | 130 KG | 190 KG |