High pressure reactor Introduction

High pressure reactor is suitable for chemical reactions such as alkylation, amination, bromination, carboxylation, chlorination, and catalytic reduction. It can also be used for small Batch chemical production, corrosion testing, reaction calorimetry, etc.

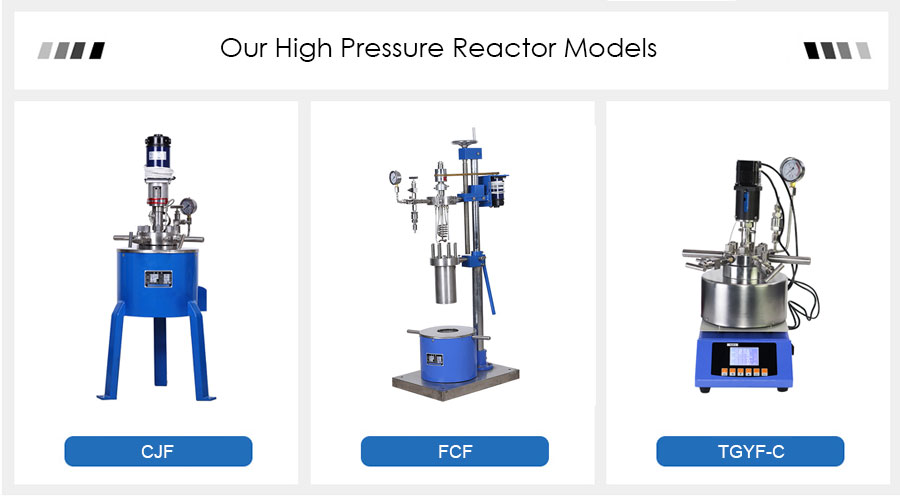

We have four models of high pressure reactor: FCF,CJF,TGYF-C.

FCF series lab scale high pressure reactor

It is mainly composed of steering wheel, motor, air valve, vacuum gauge, kettle body cover, safety valve, heating device, controller and other components:

Kettle cover : to ensure that the medium and mixing parts are completely sealed.

Vacuum gauge : monitor the reaction pressure in the kettle in real time.

Safety valve : The reactor is equipped with a safety valve, which is fast and safe and reliable.

Controller : intelligent digital temperature control meter with self-tuning function, automatic constant temperature temperature control function, speed display and stepless speed regulation function.

CJF series lab scale high pressure reactor

It is mainly composed of motor, stirring device, vacuum meter, static seal, kettle cover, safety valve, kettle body, controller and other components:

Motor : high-power motor, powerful and stable.

Stirring device : It adopts static sealing structure, and the stirrer and motor drive are connected by magnetic coupling.

Vacuum gauge : monitor the reaction pressure in the kettle in real time.

Safety valve : Made of stainless steel, corrosion resistant.

Controller : intelligent digital temperature control meter with self-tuning function, automatic constant temperature temperature control function, speed display and stepless speed regulation function.

TGYF-C hIgh pressure Reactor with magnetic stirring

* TGYF-C Laboratory scale magnetic stirring high pressure reactor is suitable for stirring of flammable, explosive and highly permeable chemical media.

* The motor drive of the stirring tank is linked by a magnetic couple.

* It is the best reaction vessel for vulcanization and oxidation of petroleum, chemical, organic synthesis, food and other processes.

* The medium and stirring parts work in a sealed state, and there is no contact transfer to avoid stirring leakage.

Our customer use cases

High preassure reactor Application

● FCF high pressure reactor is up to 22Mpa and the temperature is up to 350℃. It is made of various structural materials and is suitable for chemical reactions such as alkylation, amination, bromination, carboxylation, chlorination, catalytic reduction, etc. It can also be used For small batch chemical production, gem soaking, corrosion testing, reaction calorimetry, etc.

● CJF high pressure reactor is more suitable for various flammable, explosive, highly toxic, precious media and other highly permeable chemical media. It is the process of petroleum, chemistry, organic synthesis, polymer material polymerization, and food. The most ideal leak-free reaction equipment for sulfurization, fluorination, hydrogenation, etc.

● TGYF-C lab scale high pressure reactor is suitable for agitation of flammable, explosive and highly permeable chemical media. It is the best reaction vessel for vulcanization and oxidation of petroleum, chemical, organic synthesis, food and other processes.

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

Why choose us?

1)High pressure reactors now in stock with fast delivery.

2) With 13 years of experience in R&D and production of rotary evaporators.

3) provide you with premium quality products and perfect after-sales service.

4) Premium quality with CE certification.

5) Factory direct sales with competitive price.

6) Provide one-stop Extraction Turnkey Solution.

Parameter

FCF lab scale high pressure reactor parameter

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) | Heating Power (kW) | Stirring Torque (N. cm) | Voltage (V/Hz) |

FCF-0.1 | 0.1 | 22 | 350 | 0.6 | 120 | 220 50/60 |

FCF-1 | 1 | 22 | 350 | 1.5 | 120 | 220 50/60 |

FCF-5 | 5 | 22 | 350 | 4 | 120 | 220 50/60 |

FCF-20 | 20 | 22 | 350 | 10 | 120 | 220 50/60 |

FCF-50 | 50 | 10 | 350 | 12 | 120 | 220 50/60 |

FCF-100 | 100 | 60 | 350 | 14 | 120 | 220 50/60 |

CJF lab scale high pressure reactor parameter

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) | Heating Power (kW) | Stirring Torque (N. cm) | Voltage (V/Hz) |

CJF-5 | 5 | 22 | 350 | 4 | 120 | 220 50/60 |

CJF-10 | 10 | 22 | 350 | 7 | 120 | 220 50/60 |

CJF-20 | 20 | 22 | 350 | 10 | 120 | 220 50/60 |

CJF-30 | 30 | 22 | 350 | 12 | 120 | 220 50/60 |

TGYF-C high pressure reactor parameter

| Model | TGYF-C | |||

| Volume | 50ml | 100ml | 250ml | 500ml |

| Pressure | 16MPa | |||

| Temperature | 300℃ | |||

| Stirring speed | 1800 r/min | |||

| Heating power | 0.6kW | 0.6kW | 0.8kW | 1.0kW |

| Material | Stainless steel 304, 316 | |||

FCF lab scale high pressure reactor parameter

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) |

FCF-0.1 | 0.1 | 22 | 350 |

FCF-1 | 1 | 22 | 350 |

FCF-5 | 5 | 22 | 350 |

FCF-20 | 20 | 22 | 350 |

FCF-50 | 50 | 10 | 350 |

FCF-100 | 100 | 60 | 350 |

CJF lab scale high pressure reactor parameter

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) |

CJF-5 | 5 | 22 | 350 |

CJF-10 | 10 | 22 | 350 |

CJF-20 | 20 | 22 | 350 |

CJF-30 | 30 | 22 | 350 |

TGYF-C high pressure reactor parameter

| Model | TGYF-C | |||

| Volume | 50ml | 100ml | 250ml | 500ml |

| Pressure | 16MPa | |||

| Temperature | 300℃ | |||

| Stirring speed | 1800 r/min | |||

| Heating power | 0.6kW | 0.6kW | 0.8kW | 1.0kW |

| Material | Stainless steel 304, 316 | |||