Our lab bioreactor is designed to meet the rigorous demands of modern laboratory fermentation. With precise control over key parameters such as temperature, pH, and dissolved oxygen, it ensures consistent and reproducible results. Ideal for microbial, mammalian, and plant cell cultures, our lab bioreactor offers scalability from small-scale experiments to larger production needs.

Advantages of our lab bioreactor

Precision Control: Equipped with advanced sensors and automated systems, our bioreactor allows for precise monitoring and control of temperature, pH, dissolved oxygen, and agitation speed.

Scalability: Designed to accommodate various volumes, our bioreactor is perfect for small-scale experiments and can be easily scaled up for larger production needs.

User-Friendly Interface: The intuitive touchscreen interface simplifies operation, making it accessible for both novice and experienced users.

Durability: Constructed with high-quality materials, our bioreactor is built to withstand rigorous laboratory conditions, ensuring long-term reliability.

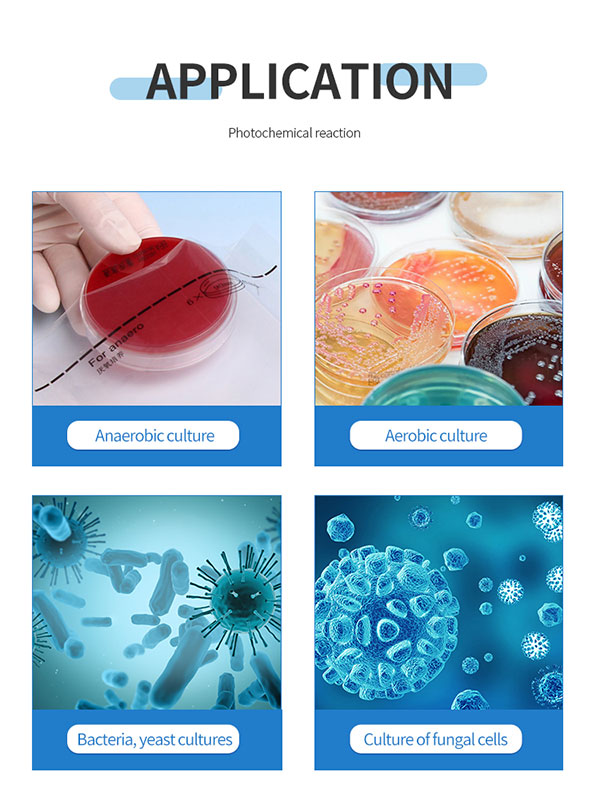

Application of lab bioreactor

Microbial Fermentation: Ideal for cultivating bacteria, yeast, and fungi for research and industrial applications.

Cell Culture: Supports the growth of mammalian, insect, and plant cells for biopharmaceutical and agricultural research.

Bioprocess Development: Facilitates the optimization of fermentation processes for the production of enzymes, biofuels, and other bioproducts.

Educational Use: Perfect for academic institutions, providing students with hands-on experience in modern biotechnological techniques.

Parameter

Tank volume | 0.5L-20L |

Aspect ratio | 1:2-3 |

Filling coefficient | 65%-80% |

Power supply | 220VAC, 50/60HZ, 10A |

Base | 304 stainless steel case with coating. |

Interface | Quick connect aviation plug/USB interface. |

Sterilization method | In-situ or ex-situ sterilization. |

Stirring system | Mechanical stirring or bottom magnetic stirring; Speed: 50~1000rpm; Accuracy: ±1rpm. |

Pressure control | Manual/automatic, measurement and control range: 0-0.2Mpa. |

PH control | Range: 2~12ph; Control Accuracy: ±0.02ph, Resolution: 0.01ph. |

DO control | Measuring range: 0-100% or 0-200%, control accuracy: ±3%; resolution: 0.1%. |

Control System | Online process control system, using color LCD touch screen + PLC form. |

Tank volume | 0.5L-20L |

Aspect ratio | 1:2-3 |

Filling coefficient | 65%-80% |

Power supply | 220VAC, 50/60HZ, 10A |

Base | 304 stainless steel case with coating. |

Interface | Quick connect aviation plug/USB interface. |

Sterilization method | In-situ or ex-situ sterilization. |

Stirring system | Mechanical stirring or bottom magnetic stirring; Speed: 50~1000rpm; Accuracy: ±1rpm. |

Pressure control | Manual/automatic, measurement and control range: 0-0.2Mpa. |

PH control | Range: 2~12ph; Control Accuracy: ±0.02ph, Resolution: 0.01ph. |

DO control | Measuring range: 0-100% or 0-200%, control accuracy: ±3%; resolution: 0.1%. |

Control System | Online process control system, using color LCD touch screen + PLC form. |