Rotary evaporator is suitable for continuous or discontinuous distillation and extraction under normal pressure or vacuum conditions, especially suitable for concentration, crystallization, separation and recovery of heat-sensitive materials. It is an essential basic instrument for chemical, pharmaceutical, universities, scientific research laboratories and other units. Our models includes:

Rotary evaporator with vacuum pump and cooling chiller

The rotary evaporator needs to be equipped with a cooling chiller and a circulating water vacuum pump.The supporting equipment for rotary evaporators of different capacities is also different. If you are using 2L and 5L rotary evaporators, you should be equipped with a desktop circulating water vacuum pump and a small cooling chiller. If you are using a 10L, 20L, 50L rotary evaporators, it should be equipped with a vertical circulating water vacuum pump and a large cooling chiller.

Application of rotary evaporator:

Rotary evaporators are

mainly used in concentration, crystallization, drying, separation and

solvent recovery in the pharmaceutical, chemical and biopharmaceutical

industries.

Our customer use cases

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

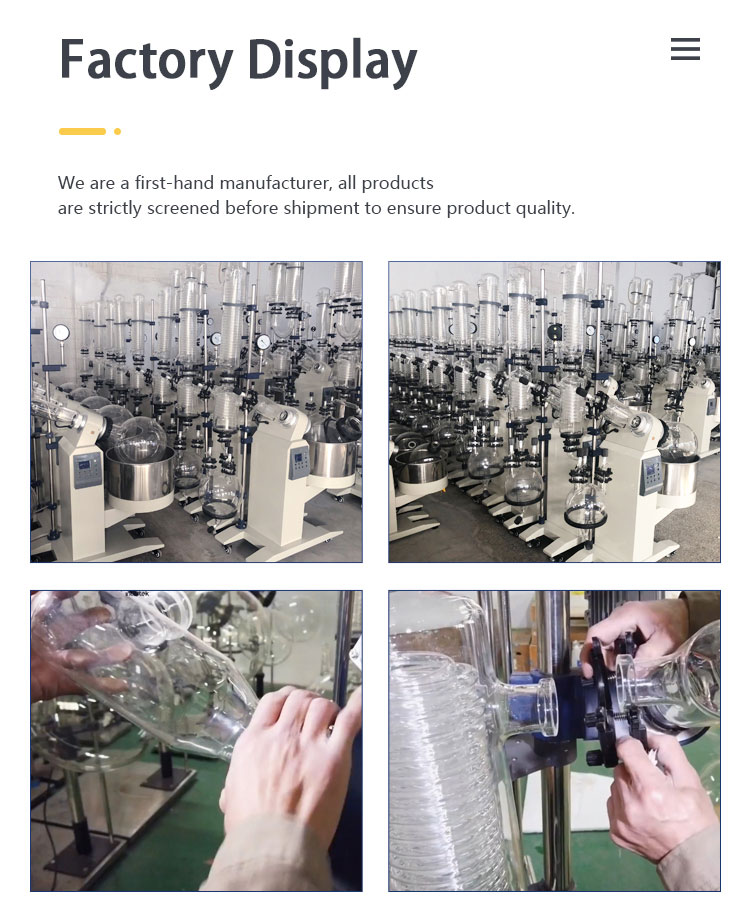

Why choose us?

1)Rotary evaporators now in stock with fast delivery.

2) With 13 years of experience in R&D and production of rotary evaporators.

3) provide you with premium quality products and perfect after-sales service.

4) Premium quality with CE certification.

5) Factory direct sales with competitive price.

6) Provide one-stop Extraction Turnkey Solution.

Parameter

Model | Rotating Motor(W) | Water(Oil) Bath Power(W) | Temperature Control Range | Evaporation Rate(H2O) | Voltage | Lifing Height(mm) |

RE-2000B | 40 | 1500 | RT~99℃ | ≥1L/h | 220V/50HZ | 0~140 |

RE-5299 | 30 | 1500 | RT~99℃ | ≥1L/h | 220V/50HZ | 0~150 |

RE-201D | 40 | 1200 | RT~399℃ | ≥1L/h | 220V/50HZ | 0~150 |

RE-301 | 40 | 1500 | RT~399℃ | ≥1.5L/h | 220V/50HZ | 0~120 |

RE-501 | 40 | 1500 | RT~399℃ | ≥1.5L/h | 220V/50HZ | 0~120 |

RE-1002 | 180 | 3000 | RT~99(250)℃ | >3L/h | 220V/50HZ | 0~220 |

RE-2002 | 180 | 5000 | RT~99(250)℃ | >5L/h | 220V/50HZ | 0~220 |

RE-5002 | 250 | 7000/9000 | RT~99(250)℃ | >9L/h | 380V/50HZ | 0~220 |

RE-2000B | 40 | 1500 | RT-99 Temperature control accuracy ±1℃ | ≥1 | 220V 50/60HZ | 0-140 |

EXRE-1002 | 180 | 3000 | 0-99(250) | >3 | 220V 50/60HZ | / |

EXRE-2002 | 180 | 5000 | 0-99(250) | >5 | 220V 50/60HZ | / |

EXRE-5002 | 370 | 7000/9000 | 0-99(250) | >9 | 380V/50HZ | / |

Model | Rotating Motor(W) | Water(Oil) Bath Power(W) | Temperature Control Range |

RE-2000B | 40 | 1500 | RT~99℃ |

RE-5299 | 30 | 1500 | RT~99℃ |

RE-201D | 40 | 1200 | RT~399℃ |

RE-301 | 40 | 1500 | RT~399℃ |

RE-501 | 40 | 1500 | RT~399℃ |

RE-1002 | 180 | 3000 | RT~99(250)℃ |

RE-2002 | 180 | 5000 | RT~99(250)℃ |

RE-5002 | 250 | 7000/9000 | RT~99(250)℃ |

RE-2000B | 40 | 1500 | RT-99 Temperature control accuracy ±1℃ |

EXRE-1002 | 180 | 3000 | 0-99(250) |

EXRE-2002 | 180 | 5000 | 0-99(250) |

EXRE-5002 | 370 | 7000/9000 | 0-99(250) |