What is solvent recycler machine?

Solvent recyclers remove soils, debris and oils from used cleaning solvent through distillation, and allow for reuse of the cleaning solvent. A solvent recovery system for used solvents can reduce solvent purchases by over 95% and reduce chemical waste disposal cost by over 90%.

Solvent recycler machine Application

Solvent recycler machine not only reduces chemical disposal costs, but also new solvent purchases. Solvent recycling equipment can recycle nearly any solvent or chemistry used in electroplating, metal finishing, paint and powder coating, parts washing, and vapor degreasing, including:

* Mineral spirits

* Paint Thinner

* Acetone

* IPA (isopropyl alcohol)

* MEK (methyl ethyl ketone)

* Xylene

* Hexane

* Various alcohols

* Chlorinated solvents (AK225, 1,2 trans-dichloroethylene / trans DCE, 3M™ Novec™, Dupont Vertrel)

* Microcare solvents

* Terpenes Toluene

* Aromatic Solvents

Benefits of solvent recycler machine

* Substantially Reduces the need to purchase new solvents

* Reduce disposal cost

* ROI in a matter of Months

* Simplify regulatory reporting

* Improves control over hazardous waste liability

* Minimize on-site storage of hazardous wastes

* Saves your company tons of money

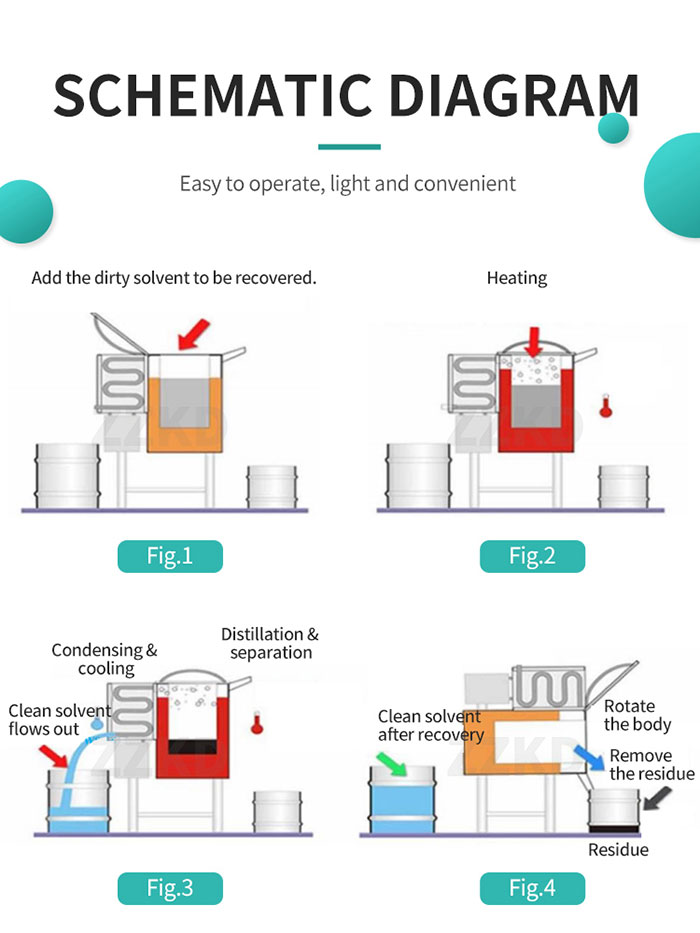

How Does a Solvent Recycler Machine Work?

1. Add the waste to be recycled;

2. Use a rag to wipe the edge of the recycling barrel mouth wall and the surface of the fuselage clean;

3. Close the lid of the barrel, and loosen the hot kerosene vent valve;

4. Place a clean recycling bucket at the solvent outlet of the recycling machine, in which the clean solvent will be retained after recycling;

5. Turn on the working switch of the recycling machine to make the equipment start to work;

6. After the solvent recovery is completed, clean up the residue in the recovery bucket;

7. Clean up equipment surface hygiene;

8. Collect the recovered solvent;

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

Why choose us?

1)Solvent recycling machine now in stock with fast delivery.

2) With 13 years of experience in R&D and production of solvent recycling machine.

3) provide you with premium quality products and perfect after-sales service.

4) Premium quality with CE certification.

5) Factory direct sales with competitive price.

6) Provide one-stop Extraction Turnkey Solution.

Parameter

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

T-40Ex | 40 | 380 | 4 | 5~200 | 150 | 95 |

T-60Ex | 60 | 380 | 5 | 5~200 | 180 | 95 |

T-80Ex | 80 | 380 | 6 | 5~200 | 210 | 95 |

T-100Ex | 100 | 380 | 8 | 5~200 | 240 | 95 |

T-125Ex | 125 | 380 | 8 | 5~200 | 240 | 95 |

T-250Ex | 250 | 380 | 16 | 5~200 | 270 | 95 |

T-450Ex | 450 | 380 | 32 | 5~200 | 270 | 95 |

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) |

T-40Ex | 40 | 380 | 4 |

T-60Ex | 60 | 380 | 5 |

T-80Ex | 80 | 380 | 6 |

T-100Ex | 100 | 380 | 8 |

T-125Ex | 125 | 380 | 8 |

T-250Ex | 250 | 380 | 16 |

T-450Ex | 450 | 380 | 32 |