What is Laboratory Mini Spray Dryer?

Laboratory mini spray dryer is the Ideal Spray Dryer for Lab & Pilot Plant Applications, they are designed for small scale spray drying purposes. The mini spray dryers show incredible easy accessibility and suitability for relatively small doses of samples. With our comprehensive guidelines and technical support, you can easily set up, operate and maintain it.

Benefits of laboratory mini spray dryer

᛫ Laboratory scale reproducible powder production

᛫ Clear view of the process due to glass assembly

᛫ Simple and fast installation

᛫ Quick and easy operation

᛫ Glass parts can be assembled and cleaned quickly by just one person

᛫ Lowest maintenance and spare parts costs

Our customer use cases

Application of spray dryer machine

It is mainly used in scientific research, laboratory, chemistry, pharmacy, biology, food laboratories and other fields in universities and colleges, for the production of milk powder, coffee powder, starch, protein powder, traditional Chinese medicine powder, serum, antibiotics, spices, etc.

Features of our mini spray dryer machine

᛫ High quality borosilicate glass, strong and easy to clean.

᛫ The tight sealing provides a good sealing environment for the working process.

᛫ The machine body is made of 304 stainless steel.

᛫ Digital PLC touch screen.

᛫ The fan can be adjusted by frequency and speed, and the operation is more free.

᛫ High recovery rate, the recovery rate of 2L spray dryer machine is more than 70%, and the recovery rate of 5L and 10L spray dryer machine are more than 90%.

᛫ Feed with a peristaltic pump.

Warehouse in USA | Canada | Spain | Thailand

We have warehouses in the United States (Los Angeles), Canada (Vancouver), Spain (Valencia), Thailand (Bangkok), and have a large inventory,no matter which country you are in, you are guaranteed to receive the goods as quickly as possible.

Why choose us?

᛫ Spray dryers now in stock with fast delivery.

᛫ With 13 years of experience in R&D and production of spray dryers.

᛫ Provide you with premium quality products and perfect after-sales service.

᛫ Premium quality with CE certification.

᛫ Factory direct sales with competitive price.

Parameter

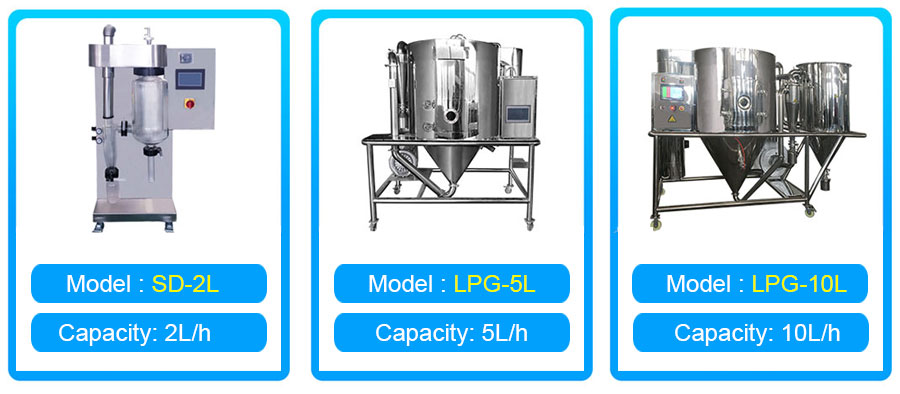

Model | Inlet temperature (°C) | Moisture maximum evaporation (kg/h) | Rotating speed (r.p.m) | Diameter of spray disc (mm) | Electric heating power (kw) |

SD-2L | 140-300 | 2 | 25000 | 0.7 | 3 |

LPG-5L | 140-350 | 5 | 25000 | 50 | 9 |

LPG-10L | 140-350 | 10 | 25000 | 50 | 20 |

Model | Inlet temperature (°C) | Moisture maximum evaporation (kg/h) | Rotating speed (r.p.m) |

SD-2L | 140-300 | 2 | 25000 |

LPG-5L | 140-350 | 5 | 25000 |

LPG-10L | 140-350 | 10 | 25000 |