The hydrothermal synthesis reactor is a reactor provided for synthesizing chemical substances under a certain temperature and certain pressure. It can be used for small-dose synthesis reactions; it can be used for sample dissolution pretreatment in the analysis of atomic absorption spectroscopy and plasma emission; it can also be used for The purpose of quickly digesting insoluble substances is achieved by using the strong acid or strong alkali and high temperature and high pressure airtight environment in the tank. It is widely used in the research and production of petrochemical, biomedical, material science, geochemistry, environmental science, food science, commodity inspection and other departments. It is a commonly used small reactor for scientific research in university teaching and scientific research units.

The operation method of the hydrothermal synthesis reactor:

1. Pour the substance to be reacted into the PTFE bushing or PPL bushing, and ensure that the feeding coefficient is less than 0.8.

2. Make sure that the lower gasket of the kettle body is in the correct position (the convex side faces down), then put in the PTFE bushing or PPL bushing and the upper gasket, first tighten the kettle lid, and then use the screw to screw the kettle lid tightly .

3. Place the hydrothermal synthesis reactor in the heater, and heat it up to the required reaction temperature according to the specified heating rate. (less than the specified safe operating temperature).

4. When it is confirmed that the intra-abdominal temperature is lower than the boiling point of the solvent of the reactant, the lid of the kettle can be opened for subsequent operations. When the reaction is over to cool it down, it should also be operated in strict accordance with the specified cooling rate to facilitate safety and the service life of the reactor.

5. After confirming that the temperature in the kettle is lower than the boiling point of the solvent of the reactant, firstly use the screw to loosen the lid of the kettle, and then open the lid of the kettle.

6. The hydrothermal synthesis reactor should be cleaned in time after each use to avoid corrosion. Special attention should be paid to cleaning the sealing parts of the kettle body and the kettle cover line, and to prevent them from being bruised and damaged.

Performance characteristics of hydrothermal synthesis reactor:

1. Good corrosion resistance, no overflow of harmful substances, reduce pollution, and safe to use.

2. After heating up and increasing pressure, it can quickly and non-destructively dissolve samples that are difficult to dissolve under conventional conditions and samples containing volatile elements.

3. The appearance is beautiful, the structure is reasonable, the operation is simple, the analysis time is shortened, and the data is reliable.

4. There is a polytetrafluoroethylene bushing inside, which can generate care, and can resist acid and alkali.

5. It can replace the platinum crucible to solve the problem of sample solution processing for the analysis of trace elements in high-purity alumina. The high-pressure digestion tank used in the oven, also known as sample dissolver, pressure-dissolving bomb, hydrothermal synthesis reactor, digestion tank, and polytetrafluoroethylene high-pressure tank, is a powerful assistant for the digestion of samples in the determination of trace elements and trace elements. Sample pretreatment to digest heavy metals, pesticide residues, food, sludge, rare earth, aquatic products, organic matter, etc.

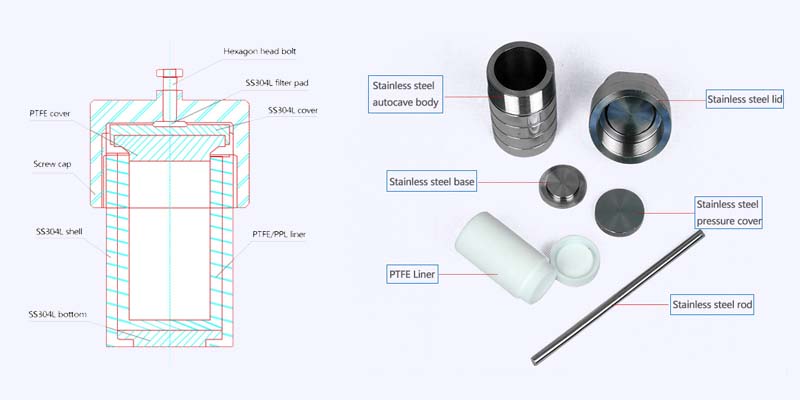

Hydrothermal synthesis reactor material:

①The body of the kettle is made of 304 high-quality stainless steel, sealed with circular tongue and groove, and the manual screw is firm. It has good sealing performance, high safety factor, less acid and solvent consumption, and easy to use!

The material of the inner tank is polytetrafluoroethylene (PTFE referred to as F4), and its characteristics:

1. High temperature resistance: operating temperature -200~+220℃;

2. Low temperature resistance: -196℃ can keep 5%;

3. Corrosion resistance: resistance to strong acid, alkali, aqua regia and various organic solvents;

4. Insulation resistance: dielectric properties have nothing to do with temperature and frequency;

5. High lubrication: the lowest friction coefficient among solid materials;

6. Non-adhesion: no adhesion to any substance; strong self-wetting: the coefficient of friction in solid materials is 0.04

7. Non-toxic: It is physiologically inert and can be implanted into the human body; anti-aging can be used in the atmosphere for a long time

8. Anti-pollution: the blank value of metal elements is low, the lead content is less than 10-11 g/ml, and the uranium content is less than 10-12 g/ml;

9. Anti-leakage: When dropped from a height of 1.2 meters from the ground, the bottle body does not break, the bottle cap does not fall off, and there is no damage or leakage.

Precautions for hydrothermal synthesis reactor:

1) Experimental environment

The reactor should be placed indoors, and the laboratory should be well ventilated. The safety valve discharge port of the autoclave should be connected to the outdoor, and the laboratory should have a safety outlet directly leading to the outdoor or channel. The experimental operating procedures and warning signs should be posted beside the autoclave or the muffle furnace and oven used for heating the hydrothermal autoclave.

2) Equipment inspection

Regularly check whether the container equipment is damaged, check whether the inside of the autoclave, agitator, rotating parts, ancillary equipment, indicating instruments, safety valves, pipelines and valves meet the safety requirements; check the kettle body, lid and all Whether there are any abnormal phenomena such as cracks, deformation and leakage in the welding seam; the corrosion condition of the inner surface of the kettle body and the kettle cover; whether the safety accessories can work normally; whether the condensate drainage device is normal; whether all the fasteners are loose, etc.

3) Safety accessories

Before the experiment, the safety accessories such as the safety valve should be checked to be in good condition and checked regularly; the autoclave needs to use a special pressure gauge, generally a special pressure gauge for oxygen.

4) Operational Specifications

Experimenters who use the hydrothermal synthesis reactor must be trained, familiar with the structure and performance of the reactor, and proficient in the equipment operating procedures. It is strictly forbidden to work under the conditions of over-temperature and over-pressure.

5) Personal protection

Experimenters wear appropriate personal protective equipment, a knee-length lab coat, chemical splash goggles, shoes that don't show the foot (non-mesh upper), heat-resistant gloves, and a full-face impact shield during all phases of the procedure Wait.

Hydrothermal synthesis reactor cleaning:

1. Pickling method. Add about 1:5 mixed dilute solution of nitric acid and water prepared in the open container into the hydrothermal reaction kettle. The heating temperature should not exceed 140 °C, and the ratio of the mixed solution of nitric acid and water should be strictly controlled.

2. You can also choose cleaning reagents according to the type of laundry to be washed, and ensure safe and appropriate cleaning under the guidance of the instructor.

The hydrothermal reactor produced by ZZKD has stable performance and easy operation. In addition, we have glass reactors, stainless steel reactors, high pressure reactors and other reactor equipment. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain and Thailand.

If you want to know about our products, or want to buy our equipment, please feel free to contact us, ZZKD will guide you how to use the hydrothermal reactor correctly and provide you with the best price for the hydrothermal reactor.