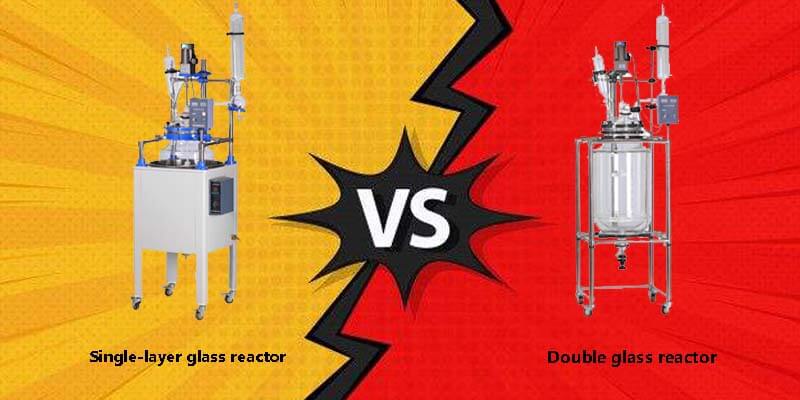

Working principle of glass reactor:

1. The working principle of the single-layer glass reactor: the single-layer glass reactor directly heats the reactor body through a layer of silver film heating plate, so that the materials in the reactor can be kept at a constant temperature and can be stirred. The material is reacted in the reactor, and the evaporation and reflux of the reaction solution can be controlled.

2. The working principle of the double-layer glass reactor: through the interlayer of the double-layer reactor, a constant temperature (high temperature or low temperature) heating or cooling liquid is injected, and the reactor is heated or cooled at a constant temperature. In a closed reaction kettle, stirring and reacting under normal pressure or negative pressure, and the evaporation and reflux of the reaction solution can be controlled. After the reaction is completed, the material can be discharged from the discharge port at the bottom of the kettle, and the operation is extremely convenient. It is an ideal equipment for modern chemical sample experiments, biopharmaceuticals and new material synthesis.

The difference between single-layer glass reactor and double-layer glass reactor:

The double-layer glass reactor can complete high temperature, low temperature and vacuum reaction experiments at the same time. It is simple to operate, the reaction process is clear at a glance, and it is convenient to control the reaction process. It is an ideal test and production equipment for modern synthetic chemical industry, biopharmaceuticals and new material preparation. The double-layer glass reactor is designed with double-layer glass, and the inner layer is equipped with a reaction solvent, which can be used for stirring reaction. The double-layer glass reaction kettle can be stirred and reacted under normal pressure or negative pressure according to the requirements in the closed glass reaction kettle under the set constant temperature, and can be used for reflux and distillation of the reaction solution. The double-layer glass reaction kettle is a Ideal equipment for modern fine chemicals, biopharmaceuticals and new material synthesis.

The double glass reactor is based on a multifunctional single reactor. And after years of improvement, the reactor is based on a single multifunctional glass reactor, which realizes convenient high and low temperature control, rapid temperature rise, cooling requirements in the experimental process, modern laboratory, chemical, pharmaceutical and other requirements. In terms of differences, the body of the double-layer glass reactor is divided into two layers, and the middle part of the outer layer and the inner layer is called the interlayer. The heating of the double-layer glass reactor is completely accomplished through the interlayer.

Features of single-layer glass reactor:

1. Sealed PTFE material has strong sealing, anti-corrosion and wear resistance;

2. Electronic stepless speed regulation, stable operation;

3. Clearly display the control and data information plane, and the speed is obvious;

4. Intelligent temperature sensor, digital display temperature;

5. Distillation reflux can be carried out at the same time;

6. Large-diameter discharge valve, which can discharge solid and liquid materials;

7. Large diameter cleaning port, easy to clean;

8. Double return, integrated standard port condenser;

9. The main structure is made of stainless steel and aluminum alloy;

10. Stable, beautiful and durable.

Features of double-layer glass reactor:

1. Variable frequency speed regulation, geared motor, constant speed, no brushes, no sparks, safe and reliable, and can work continuously.

2. All glass is made of high borosilicate glass, which has excellent chemical and physical properties.

3. The overall stainless steel column-type mobile frame structure and the six-port reaction kettle cover. Large mouth design, easy to clean, standard mouth can be equipped with distillation synthesis devices such as reflux, liquid addition, temperature measurement, etc.

4. The stainless steel-coated PTFE stirring paddle of the double-layer glass reactor is suitable for mixing liquids with low viscosity.

5. The lower discharge port flange and tetrafluoro valve, in the container, the lower material can be disassembled, which is convenient for the solid material to be discharged completely and quickly.

6. Alloy steel mechanical seal, PTFE connection port, maintain high-precision seal during work.

7. The sensor probe has high temperature measurement accuracy and small error.

Steps for usage:

1. Before use, check whether the power supply voltage is consistent with the specifications provided on the machine nameplate.

2. Plug in the power plug, turn on the power switch on the inverter, and use the speed control knob to select the appropriate speed. The flow of the material and the power of the motor speed may resonate at a certain point. Please change the speed of the motor to avoid resonance.

3. After the stirring rod is installed, it must be rotated by hand, and pay attention to whether the concentricity is good. If the concentricity is not good, loosen the re-clamp, turn on the power after the clamp is correct, and adjust gradually from slow to fast.

4. Using the stirring rod regulator, the stirring leaves can be moved up and down 5cm as needed.

5. If the sealing performance of the kettle is found to be degraded, please check the rotating bearing in the agitator sleeve.

6. The glass instruments of this reaction device are all made of GG.17 low-expansion coefficient high-temperature resistant borosilicate glass. Users can prepare glass instruments such as reaction bottles. Please confirm the quasi-glass material to ensure safe use.

7. The interlayer on the high-temperature glass reactor is connected to an external circulation port. The hot oil can be used for heating reaction, and the cooling liquid can be used for low-temperature reaction. If it is heated by steam, it should not exceed 0.5K-1K. (Try not to use pressure steam for heating).

8. When the test is carried out at low temperature, the discharge valve at the bottom will be frosted. When using the valve, it must be partially thawed to prevent the glass from being broken.

9. If there are particulate objects in the solution during use, there may be leftovers on the PTFE piston of the valve when discharging. The air tightness will be affected when it is used again. Be sure to clean it after each discharge and use it again. .

FAQ:

1. Turn on the power switch, the indicator light does not light up.

Solution: If the power supply is not connected or the contact is poor, please ask a professional electrician to check the power supply and socket.

2. The fuse is short-circuited.

Solution: put the power switch in the OFF position, and then replace the fuse.

3. The power indicator is on, but does not rotate.

Solution: The rotating shaft is rusted, stop using, and the supplier's motor, the electrical box is faulty, the seven-pin plug is not connected, and the seven-pin plug is reconnected.

4. The vacuum disappears suddenly.

Solution: The glass is cracked, the switch is damaged, check the glass parts, and replace the switch.

5. There is a vacuum, but the sealing ring cannot be pumped.

Solution: If the connection of the vacuum switch leaks, please replace the sealing ring and switch.

6. Sometimes there is no vacuum.

Solution: There is dirt on the steel shaft and the connector is loose. Please remove the dirt and check the vacuum meter and vacuum pump.

7. The vacuum hose is aging.

Solution: Please replace the vacuum hose.

8. The main mandrel is loose left and right.

Solution: loosen the top screw and tighten it.

9. Motor temperature is too high, overload shutdown.

Solution: Turn the machine shaft by hand to see if it is heavy, remove the dirt on the contact part between the sealing ring and the glass shaft, and apply vacuum grease.

10. The case is live.

Solution: The heating tube has cracks and water enters, please check it by a professional electrician.

ZZKD Instrument Co., Ltd. is the main product of desktop circulating water vacuum pump, RE rotary evaporator, 20L single-layer glass reactor, 50L single-layer glass reactor, circulating water vacuum pump series, microwave reactor, magnetic stirrer, electric stirrer, water bath, electric heating jacket, vacuum drying oven, lifting table and other products.