Rotary evaporator is an evaporation instrument widely used in laboratories. It consists of a motor, a distillation bottle, a heating pot, a condenser tube, etc. It is mainly used for continuous distillation of volatile solvents under reduced pressure conditions. It is used in chemistry, chemical industry , biomedicine and other fields.

Mainly used for continuous distillation of large quantities of volatile solvents under reduced pressure. In particular, the concentration of the extract and the distillation of the receiving liquid during chromatographic separation can separate and purify the reaction product. The basic principle of the rotary evaporator is vacuum distillation, that is, under reduced pressure, when the solvent is distilled, the distillation flask is continuously rotating.

In this article, we will cover:

1. How the rotary evaporator works and how to operate

2. Rotary evaporator structure

3. Selection method of rotary evaporator and its supporting instruments

How Does the Rotary Evaporator Work and How to Operate It

The rotary evaporator is electronically controlled, and the flask rotates at a constant speed at the most suitable speed. The vacuum pump will keep the evaporating flask under negative pressure, and the evaporating flask will be rotated in a water bath and heated at a constant temperature. The solution in the flask was heated, diffused and evaporated in a rotary flask under negative pressure. The rotary evaporator system can be sealed and decompressed to 400~600mmHg; at the same time, it can also rotate at 50-160rpm to increase the evaporation area. In addition, under the action of the high-efficiency cooler, the hot steam can be quickly liquefied and the evaporation rate can be accelerated.

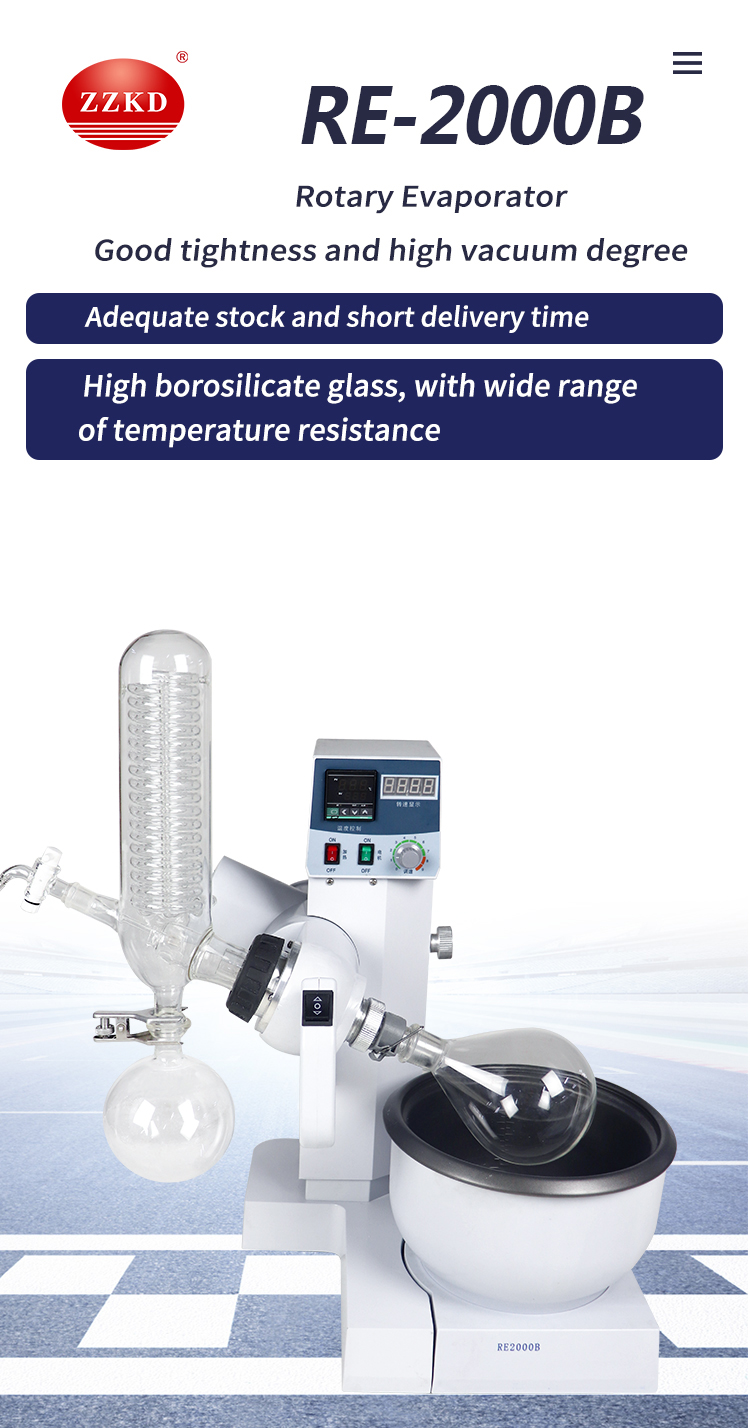

The following takes RE2000B as an example to tell you how to operate the rotary evaporator.

(1) Preparation

After assembling the machine, connect the cryopump and vacuum pump according to the schematic diagram of the connection method of the supporting equipment;

1. Turn on the cooling chiller (refer to the cooling chiller manual for details);

2. Turn on the vacuum pump, (refer to the vacuum pump manual for specific operation), start vacuuming, and start feeding when the vacuum gauge maintains the maximum vacuum for a period of time.

(2) Feeding

3. Feeding method: Pump the rotary evaporator into a negative pressure state, open the feeding valve, and the sample will be directly pumped into the rotary bottle.

It is recommended to add no more than half of the spinner bottle per addition.

(3)Control pane

(4) Operating the bathtub

4. Adjust the height of the bath so that the spinner bottle is placed in the water bath.

5. Pour pure water into the bath, submerge 1/2 of the rotating bottle, and it will not overflow.

6. Set the temperature

Method: Turn on the heating switch, set the temperature and exit the setting procedure.

7. Rotation settings:

Method: Turn on the motor switch, turn the speed control knob, and adjust to the required speed.

Note: Before turning on the motor switch, please turn the speed control knob counterclockwise to the end.

(5) Shutdown.

8. Turn off the heating switch and turn off the motor switch;

9. Release the vacuum inside the rotary evaporator;

10. Raise the spinner so that the spinner is clear of the bath. (After turning off the heating, the water bath or the spinner will not cool down immediately, it will still be hot, be careful of burns!).

11. Remove the spinner and receiver bottles.

Other models of rotary evaporator:Click to Consult

Rotary Evaporator Structure

The rotary evaporator is mainly composed of: motor, distillation bottle, vacuum system, heating pot, condenser tube and other parts.

1. Rotary motor

The operation of the rotary motor requires electric drive, and the operation of the motor on the rotary evaporator requires a uniform speed operation, so that the distillation flask is driven to rotate at a uniform speed. It should be said that such a rotation method is more suitable for various experiments. required.

2. Evaporating glass tube

Here we mainly understand the two important functions of the evaporating glass tube. On the one hand, the evaporation glass tube can achieve the purpose of support and protection when the sample is rotated. Another function is that the political and legal glass tube can realize the vacuum device to do the sample extraction work.

3. Vacuum device

It should be known that the vacuum device on the rotary evaporator can greatly reduce the overall air pressure on the rotary evaporator, which is conducive to the normal operation of the experiment.

4. Fluid heating pot

The main function of the accessories on such a distillation apparatus is to heat the sample, and then better control the required temperature to achieve the required temperature.

5. Condenser

The main purpose of use: to condense the sample for easy collection. This article will provide a one-stop solution for fruit drying.

Rotary evaporator and its supporting instrument purchase method

1. Factors affecting the efficiency of rotary evaporator

For machines of the same specification, there are mainly: steam temperature, vacuum degree and cooling water temperature. Restricted by the heat resistance of some materials, it is impossible to increase the steam temperature indefinitely during operation, so the high vacuum degree and the low cooling water temperature are the two main factors for increasing the rate.

2. The core technology of rotary evaporator

Under the corrosion of various solvents and in the state of motion, whether the system can maintain a high degree of vacuum is the main criterion for measuring the rotary evaporator. It is sealed with Teflon material and glass, which is resistant to various solvents and has a durable and reliable airtightness. It can maintain high vacuum degree above -0.098MPa.

3. Selection of rotary evaporator models

2L, 3L, and 5L machines are suitable for laboratory and small sample tests; 5L, 10L, and 20L are suitable for pilot tests; 20L and 50L are suitable for pilot tests and production, especially for the extraction of materials that need to avoid metal ion contamination.

4. The difference between vertical condenser and inclined condenser

Vertical condensers are gradually becoming popular due to their small footprint. Large-capacity evaporators generally use vertical condensers, but there is no difference between the two instruments in essence.

5. Rotary evaporator and other types of evaporators

The rotary evaporator has a small, compact structure, intuitive work, and no metal ion contamination. It is suitable for laboratory, production pilot test and extraction of precious materials, and its sealing performance is comparable to that of foreign machines.

6. Selection of vacuum pump

We recommend various solvent-resistant circulating water vacuum pumps, which can be evacuated to -0.098MPa, which can meet various application requirements.

ZZKD Machinery Instrument Equipment Co., Ltd. is a comprehensive manufacturer specializing in R&D, production, sales, laboratory, and biochemical pharmaceutical equipment, especially extraction equipment, reaction equipment, drying equipment, etc. 13 years of production and export experience and a series of ISO9001 and CE certificates, with warehouses in the United States, Spain and Thailand.

If you want to know about our products, or want to buy our equipment, please feel free to contact us, ZZKD will offer you the best price for rotary evaporators.